Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: CHF5100-SV

Brand: Rainbow

Type: Preform Injection

Structure: Horizontal

Plastic Type: Thermoplastic

Plasticizing Way: Screw Type

Clamping Way: Hydraulic & Mechanical

Automation: Automatic

Computerized: Computerized

Certification: CE

Packaging: Wooden Pallet

Productivity: 20 Sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 20 Sets

Certificate: CE

Payment Type: L/C,T/T,D/P,Paypal,Western Union

Incoterm: FOB,CFR,CIF

General Description:

Rainbow CHF Series is high performance plastic Injection Molding Machine. Traditional motion customized hydraulic and electrical appliance system is adopted for this machine type. The production performance is stable and the operation of respective function is simple and convenient. The machines are mainly applied to produce different kinds of plastic civil articles for daily use and industrial products.

Machine Features:

Rainbow CHF Series Injection Molding Machine

1. MAIN FEATURES

- A variety of text can be switched.

- Manual, semi-automatic and fully automatic mode.

- Automatic movement monitoring with alarm and fault diagnosis.

- Function of slope setting can set the start and stop of movements, so as ensure the smooth movement

2. CONTROL SYSTEM

All-digital control system uses dedicated controller, multiple CPU processing division, a multi-functional automatic fault detection, alarm system, certificates 99 mold of processing procedures, with remote control interface. System is of high stability and responsiveness. System uses color LCD, manmade interface for easy operation and with a number of peripheral interfaces.

3. HYDRAULIC SYSTEM

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less than 75 dB. The medium and large machine adopts a two-way cartridge inserted valve system to improve the system of flow and speed of response, and makes the whole machine reach the best performance.

4. SERVO SYSTEM

Pressure and flow instruction from computer controller, the servo driver will compare it with the actual pressure and flow feedback, and rectify the difference by controlling the rotating speed of the servo motor. In this way, the control of injection molding is not only accurate but also fast, and the repeatability of the products high as well.

Machine Specifications:

| Description | Unit | CHF5100-SV | |||

| International Size Rating | 3220 | ||||

| Injection Unit | A | B | C | D | |

| Screw Diameter | mm | 75 | 80 | 85 | 90 |

| Screw L/D Ratio | L/D | 21 | 20 | 19 | 18 |

| Theoretical Shot Volume | cm³ | 1727 | 1965 | 2219 | 2487 |

| Shot Weight (PS) | g | 1572 | 1788 | 2019 | 2264 |

| Injection Pressure | bar | 1865 | 1639 | 1452 | 1295 |

| Max. Screw Speed | rpm |

| 136 | ||

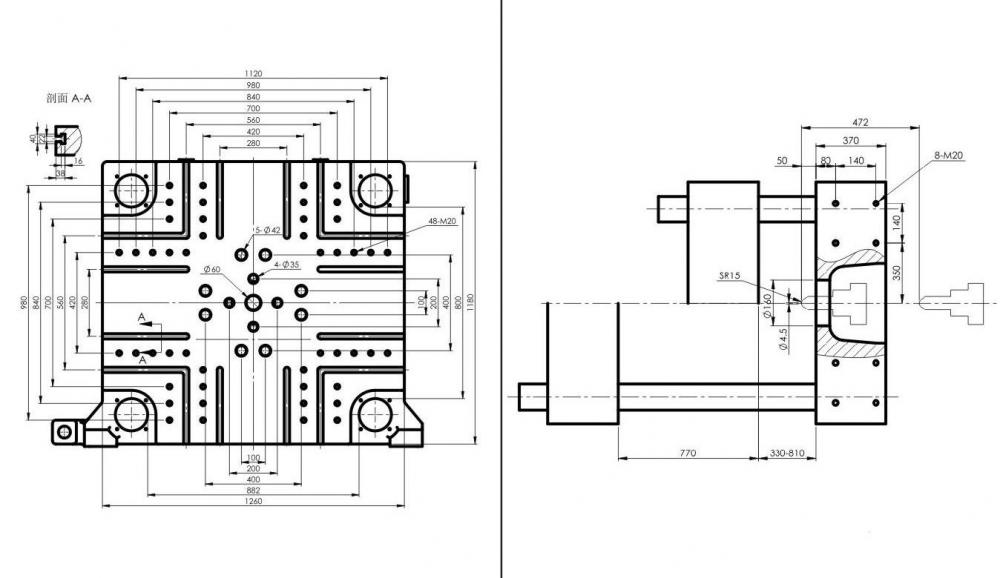

| Clamping Unit: | |||||

| Clamping Force | Kn | 5100 | |||

| Opening Stroke | mm | 770 | |||

| Distance Between tie-bars | mm | 882x800 | |||

| Max. Mold height | mm | 810 | |||

| Min. Mold height | mm | 330 | |||

| Ejector Stroke | mm | 200 | |||

| Ejector Force | Kn | 125 | |||

| Others: | |||||

| Drive Power | Kw | 55 | |||

| Heating Capacity | Kw | 33.5 | |||

| Machine Dimensions | m | 8.95x2.2x2.38 | |||

| Machine Weight | t | 26 | |||

| Oil Tank Capacity | L | 900 | |||

Product Categories : High Performance Injection Molding Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.