Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: CHC2600-SV

Brand: Rainbow

Type: Preform Injection

Structure: Horizontal

Plastic Type: Thermoplastic

Plasticizing Way: Screw Type

Clamping Way: Hydraulic

Automation: Automatic

Computerized: Computerized

Certification: CE

Packaging: Wooden Pallet

Productivity: 35 Sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 35 Sets

Certificate: CE

Payment Type: L/C,T/T,D/P,Paypal,Western Union

Incoterm: FOB,CFR,CIF

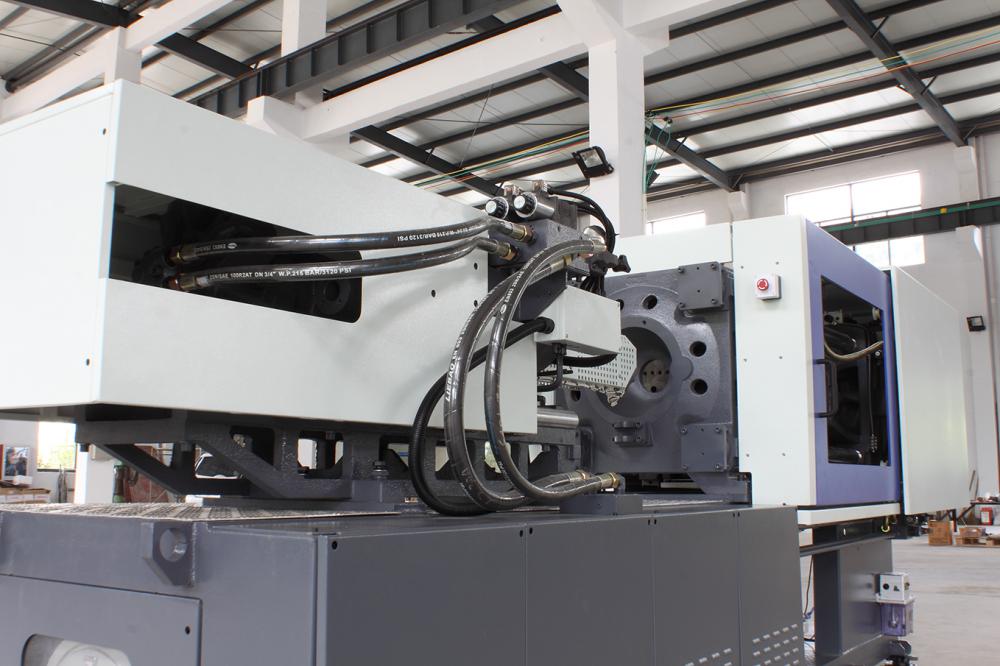

260 Ton High Quality Injection Molding Machine

General Description:

Rainbow CHC and CHF Series full-automatic horizontal plastic injection molding machine are used to make plastic products made of the thermoplastic material such as polystyrene, polyethylene, nylon, polyurethane, carbonic acid, organic glass, etc., the machine are mainly used in industry of automobile, electronics, instruments and other parts of the injection molding. The machine has advantages of the domestic and international advanced model reference, optimization of advanced structure, beautiful modeling, material, fine adjustment easy maintenance.

Machine Features:

Injection Unit:

1. Oil temperature indication

2. Adjustable such back before and after refilling

3. Auto sprue break

4. Linear transducer to control programmable injection position

5. Cold start screw prevention

6. Sliding Mechanism for hopper

7. Gas Nitrated hardened screw and Barrel

8. Screw back pressure con troll with pressure relief valve

9. Hand Operated Lubrication Unit

Plastic Bottles PET Preforms Injection Molding Machine

B. Clamping Unit

1. Five Point twin toggle locking system

2. Case Hardened toggle, Brackets and links with hardened PIN & BUSH

3. Motorized mould height adjustment for quick mould change

4. Auto tonnage setting facility

5. Low pressure precise mould protection with pressure and time setting

6. Five stage Mould closing

7. Hydraulic cushioning for consistent mould opening position

8. Linear transducer to control programmable clamp system

9. Electrical and hydraulic (Dump value) interlock safety gate

10. Moving platen with mechanical support with Teflon

11. Hydraulic Ejector with Multi stroke

12. Auto lubrication unit

PET Preforms Plastic Injection Molding Machine for Drinking Water Bottles

Ejector Unit

1. Linear transducer to control programmable ejector position

2. Multiple stroke ejection

3. Ejector forward/ backward speed adjustable

4. Ejector forward/ backward pressure adjustable

5. Two stage in ejector forward/ backward operation

6. Additional safety of sensing ejector backward position with Proximity switch

Drinking Water Bottle Preforms Injection Molding Machine

D. Hydraulic

1. Compact and Simple design

2.Sealing ring imported from Japan, a total four leak-proof protection toPrevent the oil leakage.

3. Proportional value for pressure and speed

4. Variable displacement pump system attached with pulse absorber

5. High magnetic closed-loop oil filter to effectively remove debris of the Oil, the filtration is up to 10um.

6. Easy access to hydraulic elements for ease maintenance

Drinking Water Bottle Preforms Injection Molding Machine

E. Controller

1. Display type LCD QVGA B/W of 5.7 "with 100 membrane keys

2. Multi-CPU control, with 32 bit

3. Precise temperature control, the precision is of ± 1 degree

4. Four forms of switch at the end of injection, they are time, Location, pressure, and speed.

5. Breaker and air switch are imported from Japan, the brand of Micro switch is Omron

6. Instruction cycle time of controller in 0.4 microseconds

Drinking Water Bottles Making Machine

Machine Specifications:

| Description | Unit | CHC2600-SV | ||

| International Size Rating | | 1280 | ||

| Injection Unit | | A | B | C |

| Screw Diameter | mm | 55 | 60 | 65 |

| Screw L/D Ratio | L/D | 22 | 20 | 18.5 |

| Theoretical Shot Volume | cm³ | 641 | 763 | 896 |

| Shot Weight (PS) | g | 584 | 695 | 815 |

| Injection Pressure | bar | 1999 | 1680 | 1431 |

| Max. Screw Speed | rpm | 178 | ||

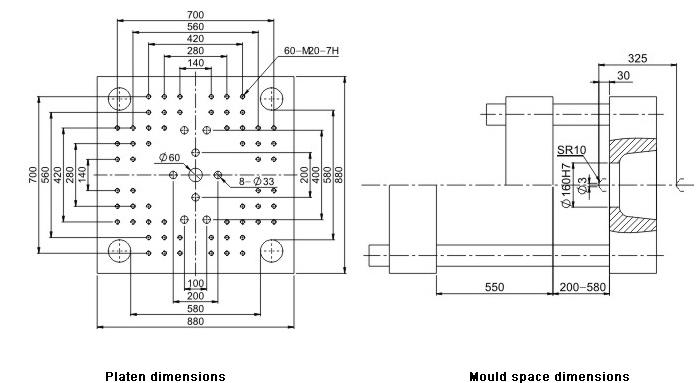

| Clamping Unit: | ||||

| Clamping Force | Kn | 2600 | ||

| Opening Stroke | mm | 550 | ||

| Distance Between tie-bars | mm | 580x580 | ||

| Max. Mold height | mm | 580 | ||

| Min. Mold height | mm | 200 | ||

| Ejector Stroke | mm | 150 | ||

| Ejector Force | Kn | 62 | ||

| Others: | ||||

| Drive Power | Kw | 30 | ||

| Heating Capacity | Kw | 13.5 | ||

| Machine Dimensions | m | 5.8x1.58x2.25 | ||

| Machine Weight | t | 8.5 | ||

| Oil Tank Capacity | L | 430 | ||

Product Categories : PET Preform Injection Molding Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.