Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: CHC1000-SV

Brand: Rainbow

Type: Preform Injection

Structure: Horizontal

Plastic Type: Thermoplastic

Plasticizing Way: Screw Type

Clamping Way: Hydraulic

Automation: Automatic

Computerized: Computerized

Certification: CE

Packaging: Wooden Pallet

Productivity: 40 Sets

Transportation: Ocean

Place of Origin: China

Supply Ability: 40 Sets

Certificate: CE

Payment Type: L/C,T/T,D/P,Paypal,Western Union

Incoterm: FOB,CFR,CIF

100 Ton Injection Molding Machine

General Description:

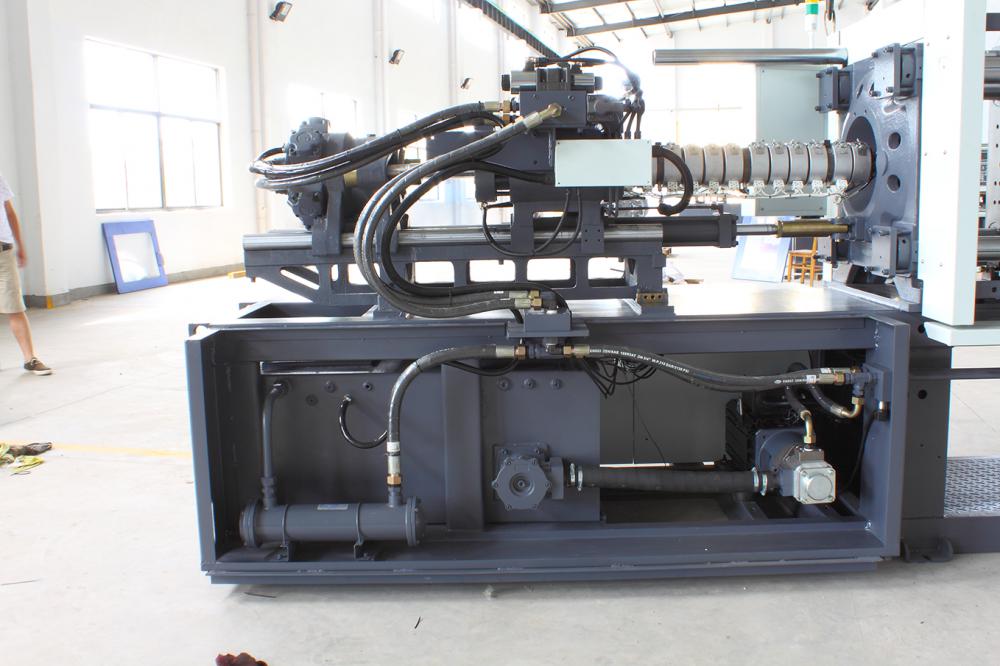

Rainbow CHC Series 100 ton injection molding machine are widely used in plastic molding industry. The machine is one of the best quality injection moulding machine made in Ningbo, China.

Machine Features:

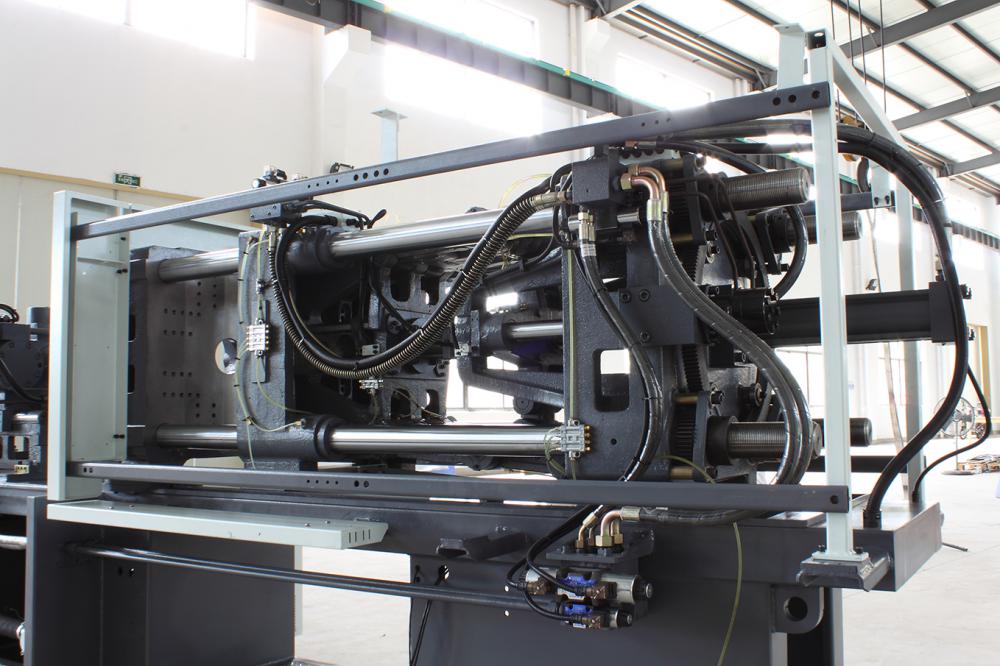

1. Double cylinder injection system, ensure the stable and precise injection

2. Self-lubrication copper bushes with high speed and low friction;

3. Standard high quality SKD61 screw tip, check ring and trust ring, 38CrMoAl screw and barrel with wonderful plasticization and long working life;

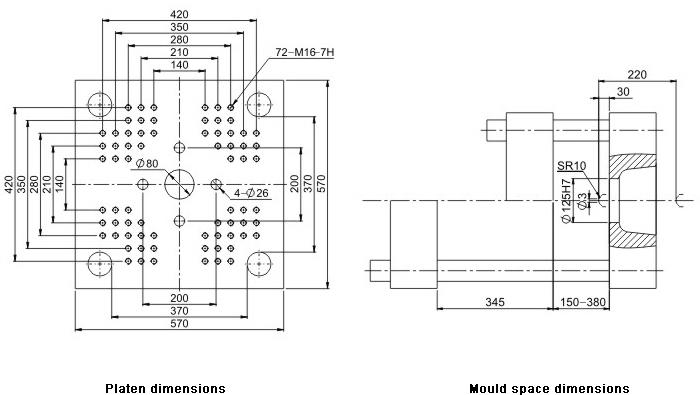

4. Optimized and FEA the clamping system, box-type ,mold platen design, strong and durable;

5. Adopt high quality copper toggle bushes on tie bars guiding parts, clamping fast and long working life;

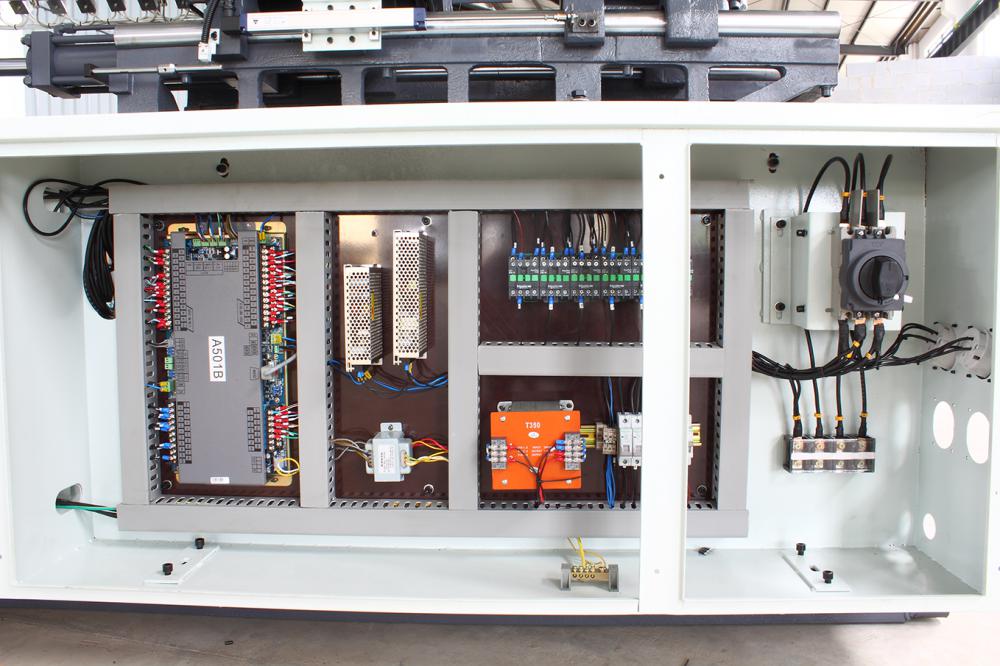

6. World famous brand electric parts, colorful LCD screen controller, PID temperature controller;

7. Large mold data saving system, fast response speed, with modernized network management function;

8. Rainbow servo system can change power ouput according to load size, save 20-80% electric energy.

9. High level imported hydraulic parts, fast response, precise and stable movement.

10. Multiple hydraulic systems for choice, such as PQ open loop system, Precise semi close loop system, Energy saving open loop system, High precise injection close loop system and High speed close loop system.

Machine Specifications:

| Description | Unit | CHC1000-SV | ||

| International Size Rating | | 290 | ||

| Injection Unit | | A | B | C |

| Screw Diameter | mm | 30 | 35 | 40 |

| Screw L/D Ratio | L/D | 22 | 20 | 19 |

| Theoretical Shot Volume | cm³ | 113 | 154 | 201 |

| Shot Weight (PS) | g | 103 | 140 | 183 |

| Injection Pressure | bar | 2640 | 1940 | 1485 |

| Max. Screw Speed | rpm | 213 | ||

| Clamping Unit: | ||||

| Clamping Force | Kn | 1000 | ||

| Opening Stroke | mm | 345 | ||

| Distance Between tie-bars | mm | 370x370 | ||

| Max. Mold height | mm | 380 | ||

| Min. Mold height | mm | 150 | ||

| Ejector Stroke | mm | 100 | ||

| Ejector Force | Kn | 33 | ||

| Others | ||||

| Drive Power | Kw | 11 | ||

| Heating Capacity | Kw | 7.2 | ||

| Machine Dimensions | m | 4.1x1.1x1.8 | ||

| Machine Weight | t | 3.5 | ||

| Oil Tank Capacity | L | 180 | ||

Product Categories : Servo Motor Injection Molding Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.