Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: CHF4000-SV

Brand: Rainbow

Type: Preform Injection

Structure: Horizontal

Plastic Type: Thermoplastic

Plasticizing Way: Screw Type

Clamping Way: Hydraulic & Mechanical

Automation: Automatic

Computerized: Computerized

Certification: CE

Packaging: Wooden Pallet

Productivity: 15 Sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 15 Sets

Certificate: CE

Payment Type: L/C,T/T,D/P,Paypal,Western Union

Incoterm: FOB,CFR,CIF

General Description:

Ningbo Rainbow Plastics Machinery Co., Ltd is a professional manufacture of plastic Injection Molding Machine ranging from 50tons to 1300tons of mould locking force(50g to 10000g of injection weight), which are mainly for foreign customers and domestic middle and high-end customers. Using new technology and good units, we make machine with C N C high-precision machine, assemble them under CE certified quality process. We supply quality machines and turnkey project. Our machine ranges covered servo energy saving series injection molding machines, high speed injection molding machines, P E T bottle injection machines, P V C fitting injection moulding machines, we can also provide high- quality mold, Auxiliary Equipment and in–mold-labeling for bucket, cup, and bowl and so on. Our products are sold all over the world. Now we are looking for agent, sales and service team, we warmly welcome you to join us!

Rainbow Products:

♦ Servo power saving machine

♦ Standard injection molding machine

♦ Variable pump machine

♦ High Speed Injection Molding Machine

♦ PET injection machine

♦ PVC injection machine

Machine Features:

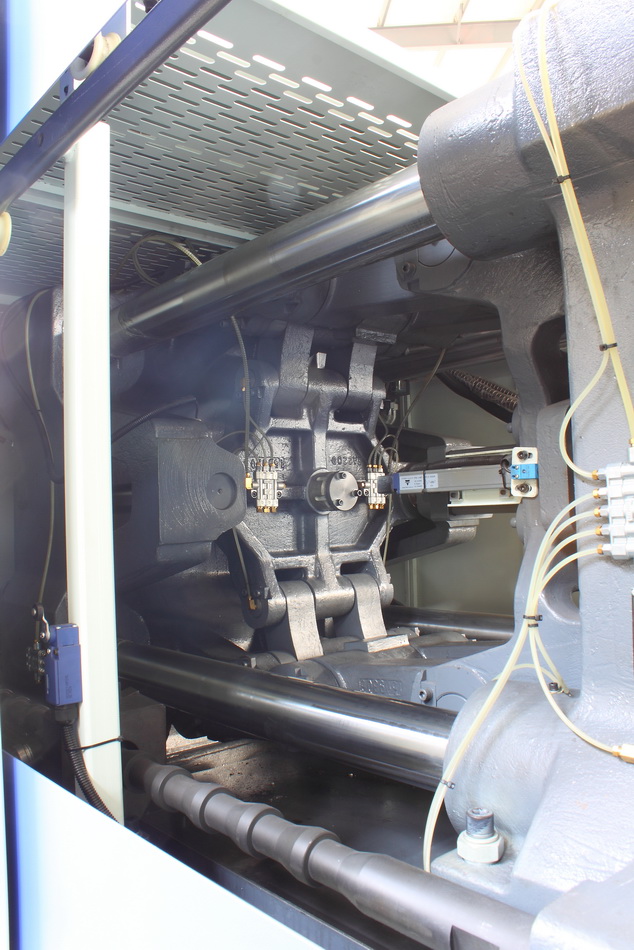

1. Quantitative Lubrication Volume Distribution System

Make sure every lubricating point be fully lubricated, oil distribution uniformed, and higher lubrication efficiency. It greatly improved the working life of the lubrication parts.

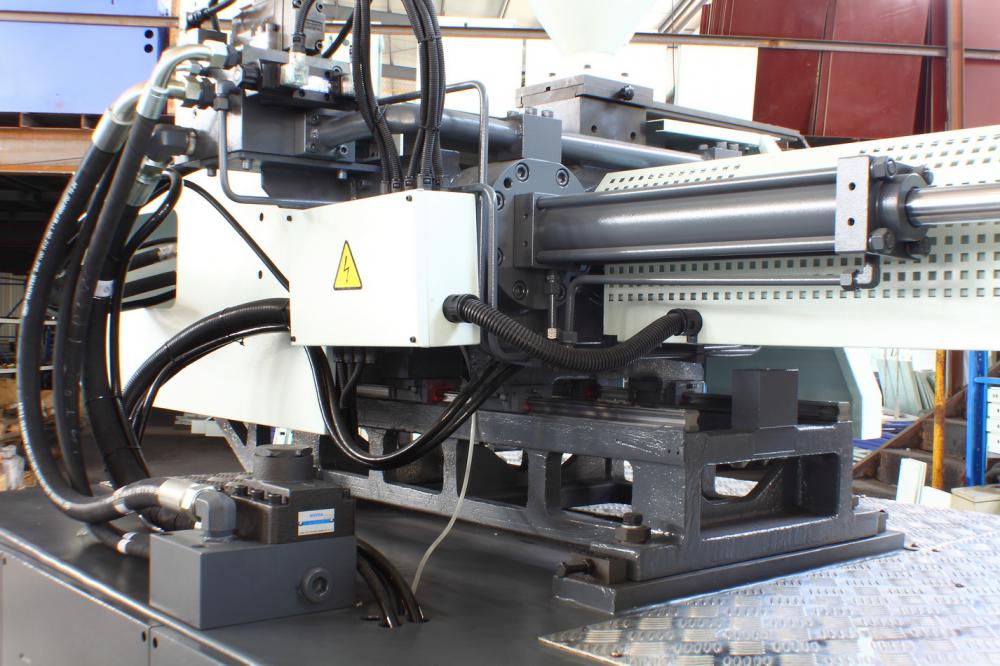

2. Special Ejector Rod Structure Design

Make it quite convenient to install counter pull ejector rod, so it greatly extends the adaptability of the machine.

3. Built-in Mechanical Safety Bar

Built-in mechanical safety bar, more beautiful and safer.

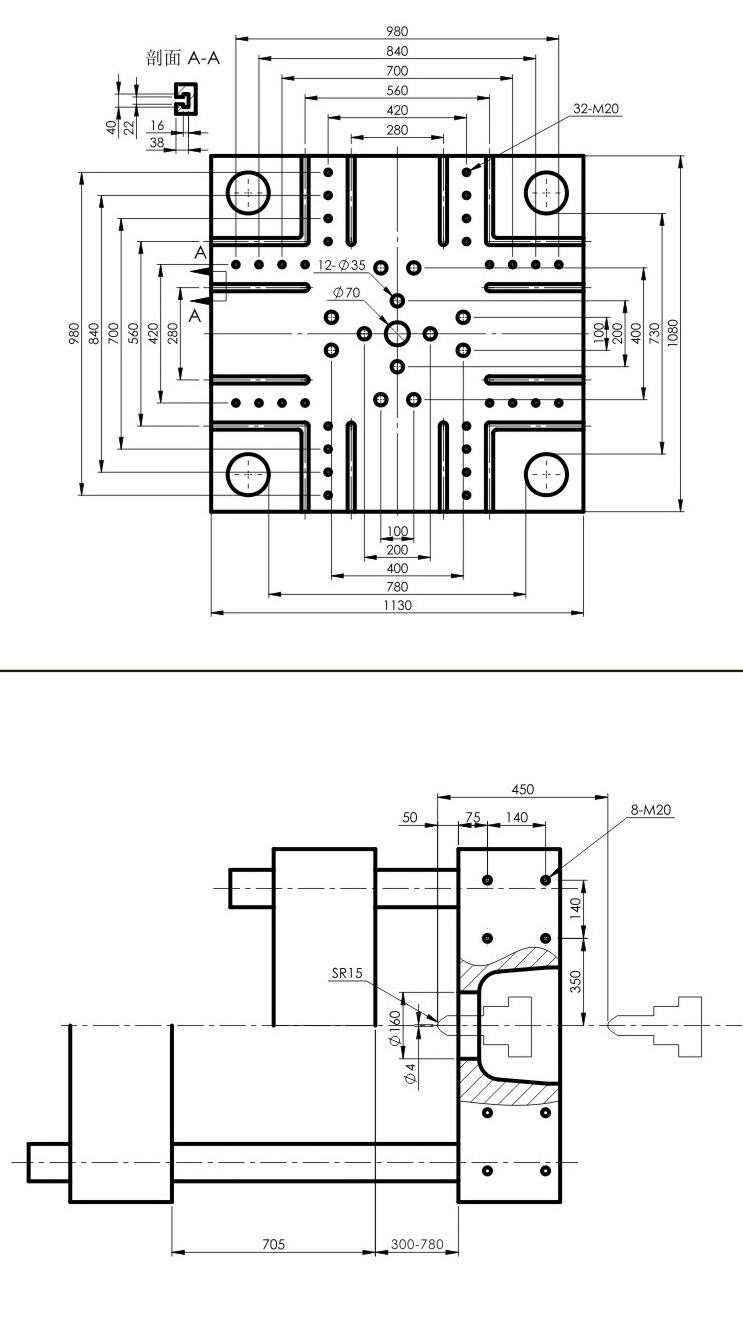

4. Larger Space between Tie-bars

Larger space between tie-bars and larger opening stroke can realize the easy installation of multi-cavity mould, and it has better adaptability for the increasing precise mold dimension

5. Paralleled Double Carriage Cylinder

Paralleled double carriage structure, avoid nozzle moving left and right, avoid melt leaking out on the touching surface.

6. Double Injection Cylinder

Double cylinder injection system, ensure the stable and precise injection; Adopt self-lubrication copper bushes, high speed and low friction; Standard with high quality SKD61 screw tip, check ring and thrust ring, 38CrMoAl screw and barrel, wonderful plasticization and long working life.

7. Double Linear Guide Rail

Double linear guide rail, faster speed, more precise and stable.

8. Energy-saving System

Adoption of servo motor and internal gear pump power system, realized the power output mode of "energy how much needed, how much given". It avoids energy waste, and the energy-saving ability can reach to 20%-80% comparing with the traditional power output mode.

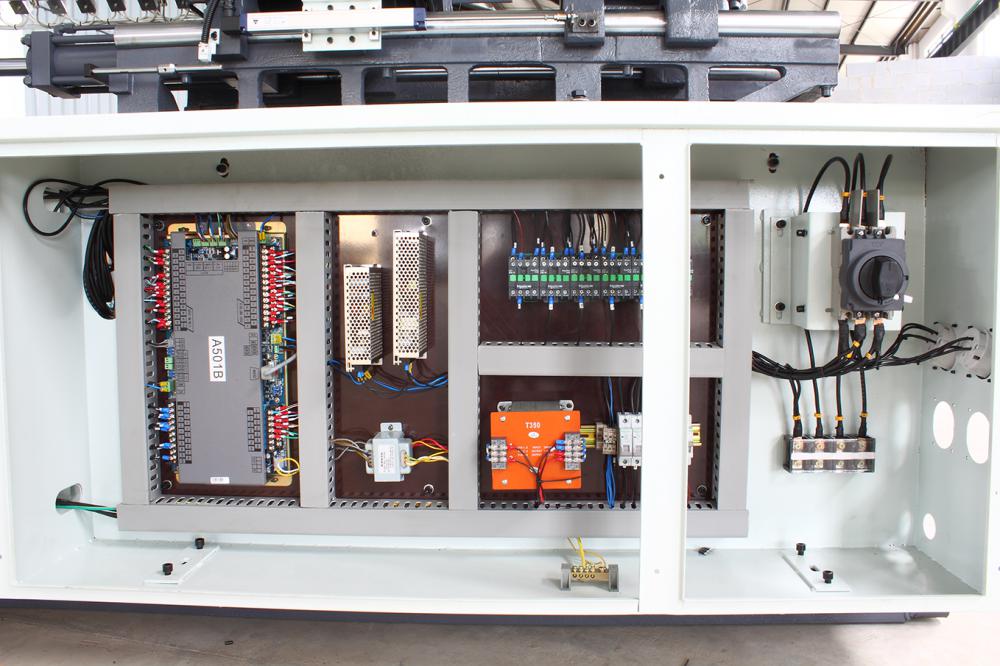

9. High Precision Controller

It requires only 0.05sec to reach the maximum power output, cycle time is substantially shortened.

10. World Famous Brands Hydraulic Parts

Adopt world-famous brands of hydraulic parts, ensure machine's precision, durability and stability.

11. Proportional Back-pressure Control

Melt back pressure adopts injection proportional back-pressure control, so the process adjustment range is wider and the product is more stable.

Machine Specifications:

| Description | Unit | CHF4000-SV | ||

| International Size Rating | | 2620 | ||

| Injection Unit | | A | B | C |

| Screw Diameter | mm | 70 | 75 | 80 |

| Screw L/D Ratio | L/D | 22 | 20 | 19 |

| Theoretical Shot Volume | cm³ | 1443 | 1657 | 1885 |

| Shot Weight (PS) | g | 1313 | 1508 | 1715 |

| Injection Pressure | bar | 1817 | 1583 | 1391 |

| Max. Screw Speed | rpm | 156 | ||

| Clamping Unit: | ||||

| Clamping Force | Kn | 4000 | ||

| Opening Stroke | mm | 705 | ||

| Distance Between tie-bars | mm | 780x730 | ||

| Max. Mold height | mm | 780 | ||

| Min. Mold height | mm | 300 | ||

| Ejector Stroke | mm | 180 | ||

| Ejector Force | Kn | 90 | ||

| Others: | ||||

| Drive Power | Kw | 45 | ||

| Heating Capacity | Kw | 29.5 | ||

| Machine Dimensions | m | 7.4x2.05x2.3 | ||

| Machine Weight | t | 18 | ||

| Oil Tank Capacity | L | 700 | ||

Product Categories : High Performance Injection Molding Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.