Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: CHC1400-SV

Brand: Rainbow

Type: Injection Blow Molding

Structure: Horizontal

Plastic Type: Thermoplastic

Plasticizing Way: Screw Type

Clamping Way: Hydraulic

Automation: Automatic

Computerized: Computerized

Certification: CE

Packaging: Wooden Pallet

Productivity: 40 Sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 40 Sets

Certificate: CE

Payment Type: L/C,T/T,D/P,Paypal,Western Union

Incoterm: FOB,CFR,CIF

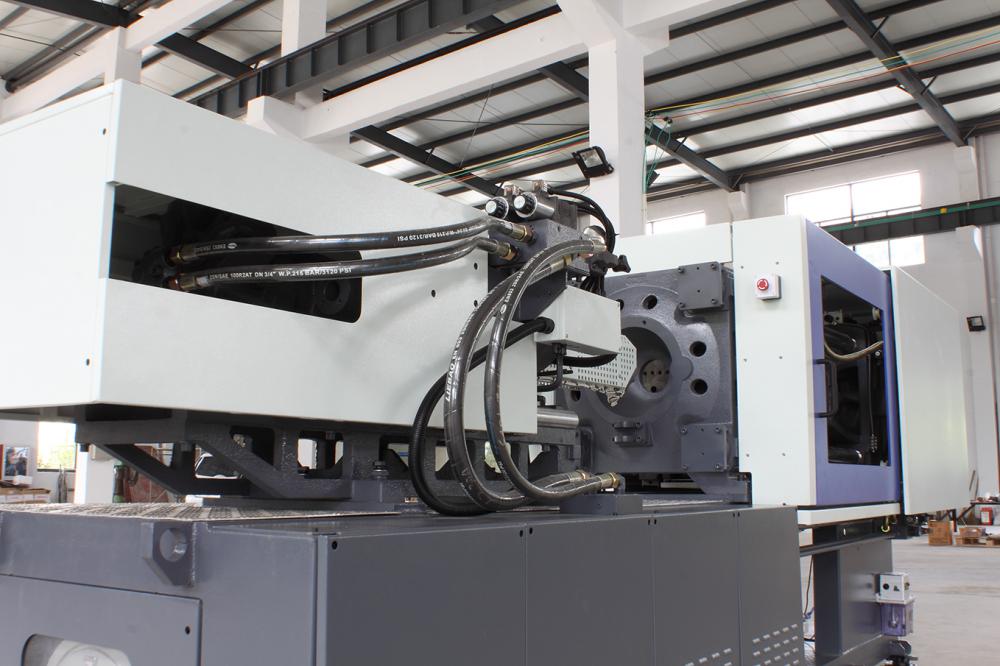

140 Ton Plastic Caps Servo Injection Moulding Machine

General Description:

Ningbo Rainbow Plastics Machinery Co., Ltd. produce and supply best quality and professional servo motor plastic Injection Molding Machine. Our factory is located in the biggest production base of China-Ningbo, Zhejiang province. All of our machines are equipped with advanced electrical and hydraulic control elements imported from the Japan, USA, Italy, German, Taiwan, etc.

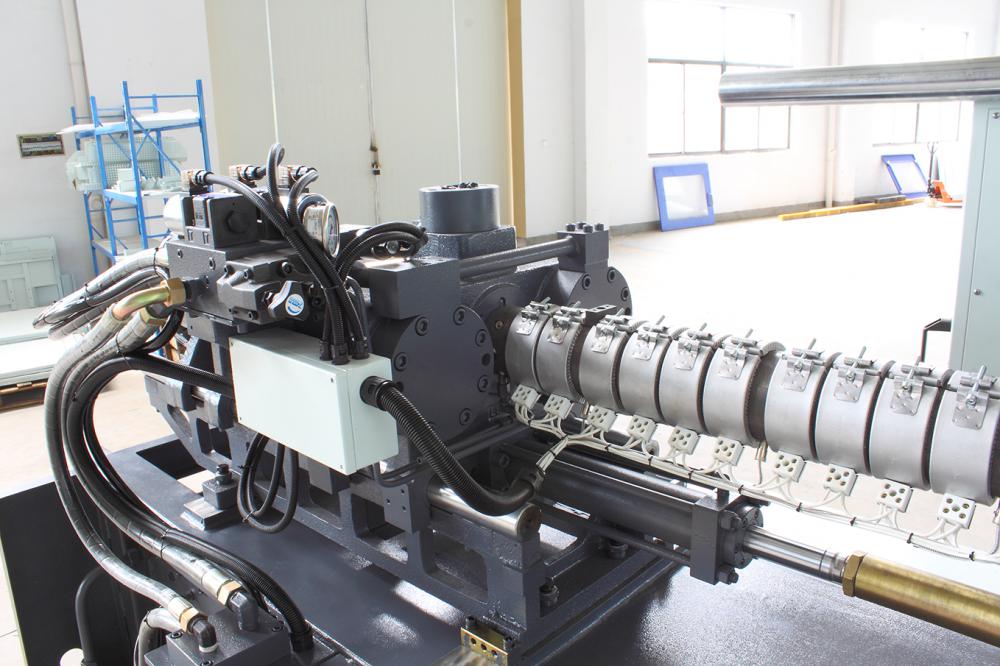

equipment:

1) Double cylinder balancing injections

2) High-torque oil-motor preplasticizing

3) Five pivots minus relief angle, double toggles, machine hinge mold locking

4) Cabinet-type holder integrates the mold plate

5) Oil motor driven gear mold adjusting

6) Storage-type grease lubricating

7) Pressure and flow whole-proportion running

8) High-performance, low-noise oil pump

9) Multi-step pressure and speed adjusting

10) High-precision position linear transducer

11) Digital memory for mold group

Injection unit:

1) Four injection pressures and speeds with three additional pressures and speeds

2) Suck back function

3) Cold start protection

4) Pre-suck back function

5) Linear displacement transducer accurately monitors injection position, providing optimum, injection accuracy and control

6) Temperature control

7) Heating Status indication

Clamping unit:

1) Three clamp close and open pressures and speeds

2) Mold protection function

3) Hydraulic ejector stroke controlled by transducer

4) Automatic hydraulic die-height adjustment driven by planetary gears system

5) Adjustable support under moving platen

6) Automatic high pressure toggle lubrication with low oil level alarm

7) Mechanical, electrical and hydraulic safety interlock devices

8) Linear displacement transducer controls clamping position

Other parts:

1) Independent core in / out pressure and speed

2) Hydraulic unscrewing sequence

3) Hydraulic oil high temperature alarm

4) System pressure gauge

5) Shot counter and reset function

6) Malfunction alarm light

7) Self-diagnostic function

8) Emergency stop buttons placed both front and rear of the machine to provide easy access

Machine Features:

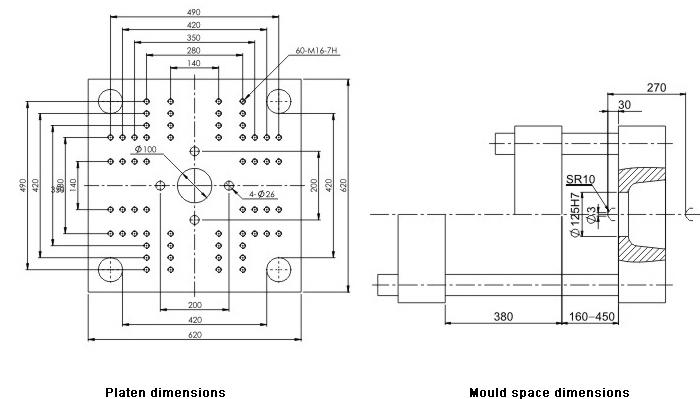

Machine Specifications:

| Description | Unit | CHC1400-SV | ||

| International Size Rating | | 400 | ||

| Injection Unit | | A | B | C |

| Screw Diameter | mm | 38 | 42 | 45 |

| Screw L/D Ratio | L/D | 22 | 20 | 18.5 |

| Theoretical Shot Volume | cm³ | 195 | 238 | 274 |

| Shot Weight (PS) | g | 178 | 217 | 249 |

| Injection Pressure | bar | 2089 | 1710 | 1489 |

| Max. Screw Speed | rpm | 200 | ||

| Clamping Unit: | ||||

| Kn | 1400 | |||

| Opening Stroke | mm | 380 | ||

| Distance Between tie-bars | mm | 420x420 | ||

| Max. Mold height | mm | 450 | ||

| Min. Mold height | mm | 160 | ||

| Ejector Stroke | mm | 120 | ||

| Ejector Force | Kn | 46 | ||

| Others: | ||||

| Drive Power | Kw | 13 | ||

| Heating Capacity | Kw | 7.4 | ||

| Machine Dimensions | m | 4.35x1.17x1.90 | ||

| Machine Weight | t | 4.5 | ||

| Oil Tank Capacity | L | 200 | ||

Product Categories : Thermoplastic Injection Molding Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.