Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: CHC1700-SV

Brand: Rainbow

Type: Preform Injection

Structure: Horizontal

Plastic Type: Thermoplastic

Plasticizing Way: Screw Type

Clamping Way: Hydraulic

Automation: Automatic

Computerized: Computerized

Certification: CE

Packaging: Wooden Pallet

Productivity: 30 Sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 30 Sets

Certificate: CE

Payment Type: L/C,T/T,D/P,Paypal,Western Union

Incoterm: FOB,CFR,CIF

General Description:

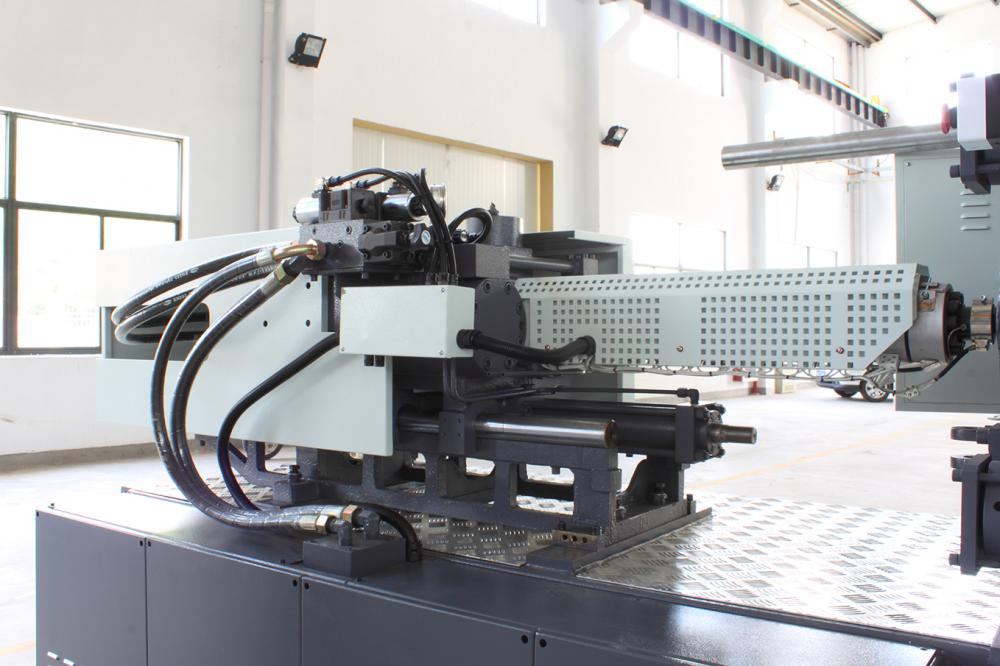

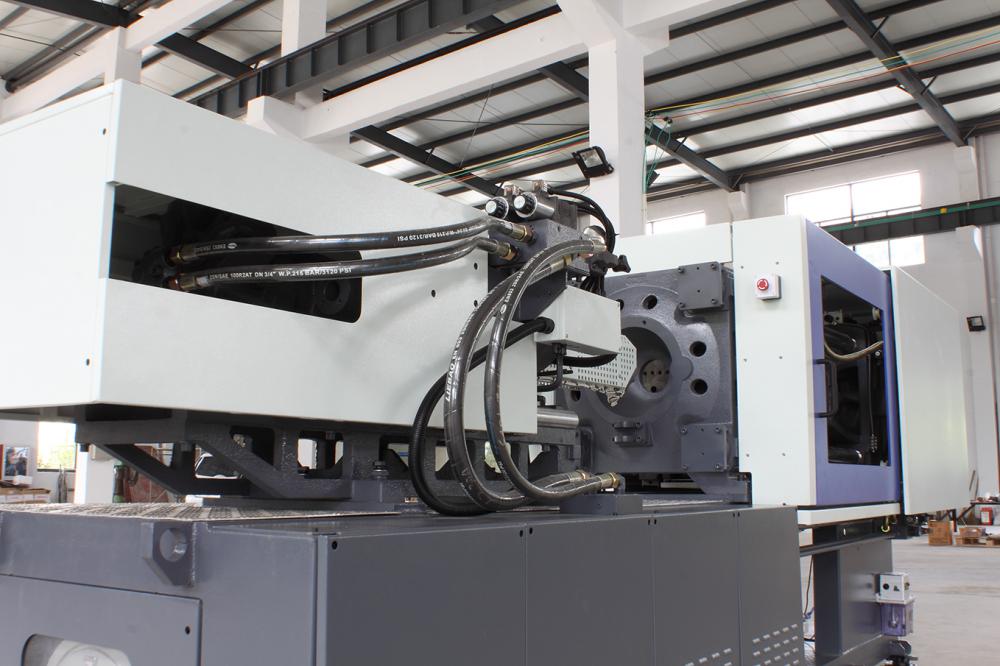

Rainbow CHC Series 170 Ton Plastic Injection Molding Machine adopts high quality servo energy saving system, the machine characterized by high energy-saving, high precision, fast response, low noise, low oil temperature, easy operation, etc. The machine equipped with high efficiency servo driver and servo motor to cooperate with good quality servo pump, it saves 40% power energy than variable pump injection molding machine and saves 70~80% power energy than normal Fixed Pump Injection Molding Machine. At the same time, the machine fixed with high precision and sensitive pressure feedback device to increase the plastic molding precision, shorten the plastic molding cycle time and increase the production capacity.

Machine Features:

1. Optimized high speed toggle clamping unit and stress of low pressure for joint ensure super precision and long working life.

2. Flexible core program, independent hydraulic pump stations to provide power.

3. High performance central lubrication system to decline the part ware, and keep long term positioning accuracy of the mould.

4. Mobile tray for wasted oil cleaning makes it easy to clean the wasted oil in clamping unit.

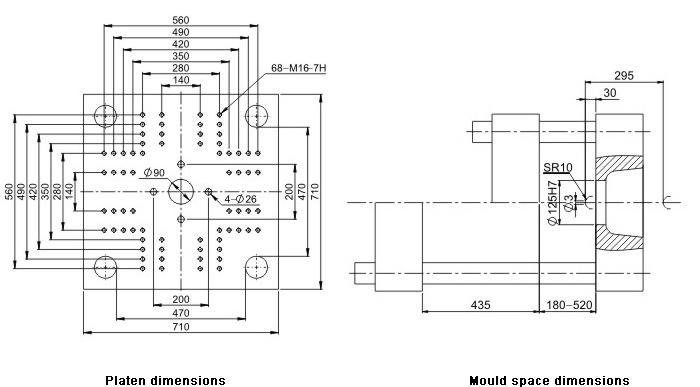

5. Super enlarged platen to meet various customer production request.

6. High precision temperature control on screw and barrel unit.

7. High quality and performance PLC computer with big display, color display and full-featured.

Machine Specifications:

| Description | Unit | CHC1700-SV | ||

| International Size Rating | | 630 | ||

| Injection Unit | | A | B | C |

| Screw Diameter | mm | 42 | 45 | 50 |

| Screw L/D Ratio | L/D | 22 | 20 | 18.5 |

| Theoretical Shot Volume | cm³ | 312 | 358 | 442 |

| Shot Weight (PS) | g | 284 | 326 | 402 |

| Injection Pressure | bar | 2032 | 1770 | 1434 |

| Max. Screw Speed | rpm | 200 | ||

| Clamping Unit: | ||||

| Clamping Force | Kn | 1700 | ||

| Opening Stroke | mm | 435 | ||

| Distance Between tie-bars | mm | 470x470 | ||

| Max. Mold height | mm | 520 | ||

| Min. Mold height | mm | 180 | ||

| Ejector Stroke | mm | 135 | ||

| Ejector Force | Kn | 46 | ||

| Others: | ||||

| Drive Power | Kw | 18.5 | ||

| Heating Capacity | Kw | 9.9 | ||

| Machine Dimensions | m | 4.93x1.3x1.98 | ||

| Machine Weight | t | 5.3 | ||

| Oil Tank Capacity | L | 260 | ||

Product Categories : Servo Motor Injection Molding Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.